Diamond tools

Diamonds are much harder than carbide. With diamond tools – at vhf these tools consist of a carbide shank with an attached diamond – you can benefit from a multiple of the tool life. Furthermore, a higher wear resistance characterizes our diamond tools.

Another great advantage of diamond tools is that they are suitable for dry machining. So, these diamonds will quickly become your best friends!

For processing plastic and non-ferrous metals, we recommend polycrystalline diamond (PCD) as cutting material. For milling highly abrasive materials such as GRP/CFRP materials or hard non-ferrous metals, CVD diamond thick-film plates are used. Tools with monocrystalline diamonds (MCD) as well as tools with polycrystalline diamonds (PCD) are available for polishing milled edges.

All diamond tools from vhf can be reground several times. The price for the regrinding service of diamond cutters depends on the tool type and its wear – for further information about this service please contact us!

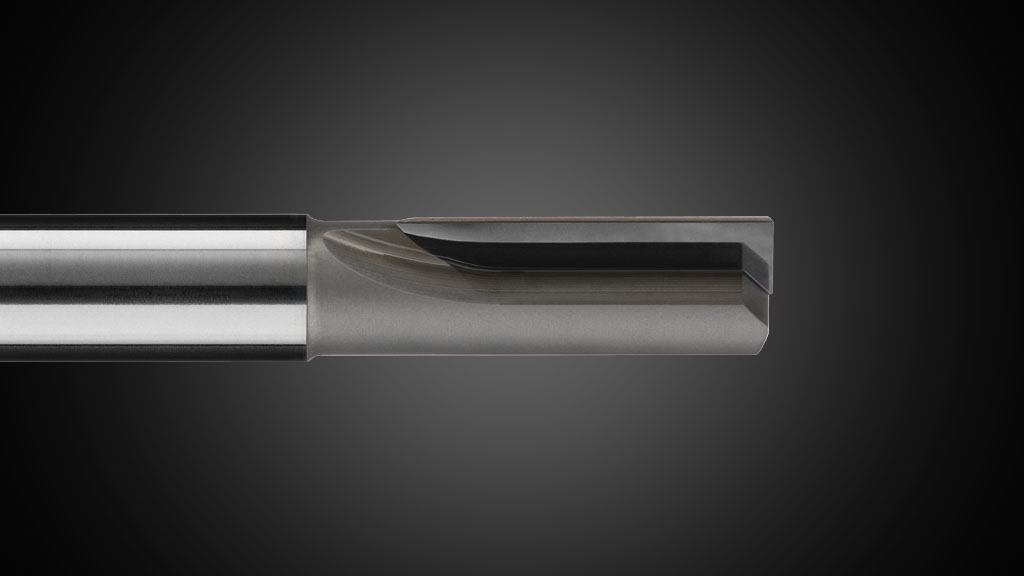

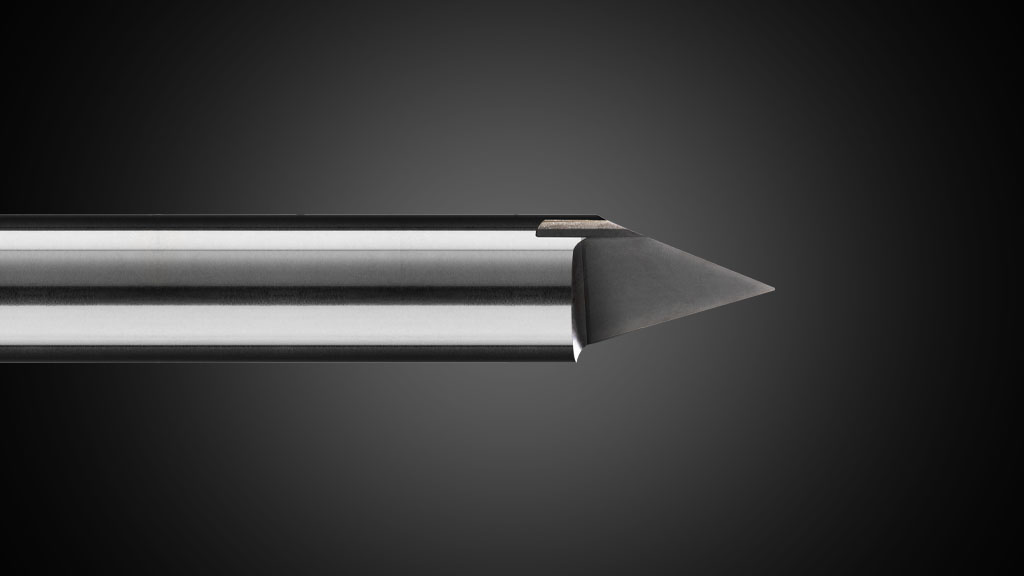

PCD single tooth cutters

Because the cutting edge of this cutter is made of diamond instead of carbide, you get a vastly improved tool life without using coolant.

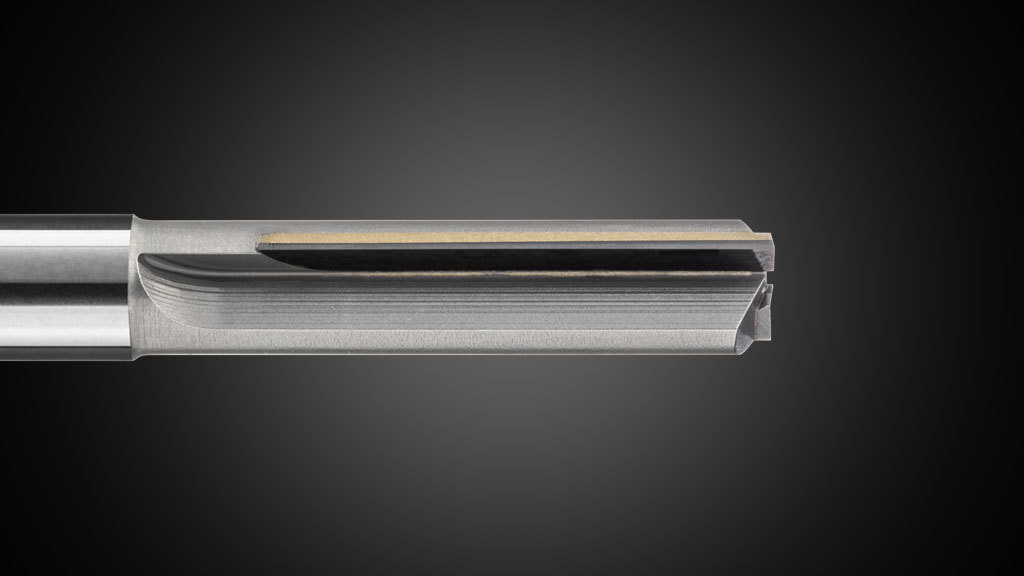

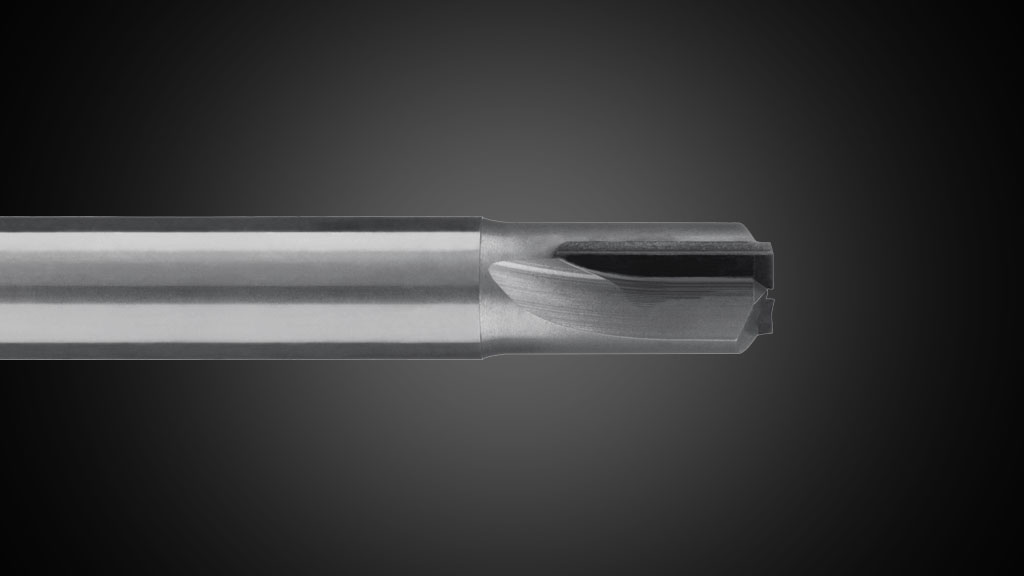

PCD double tooth cutters

The second cutting edge of this diamond tool increases the tool life again and ensures improved running smoothness. This diamond cutter is ideal for processing harder materials.

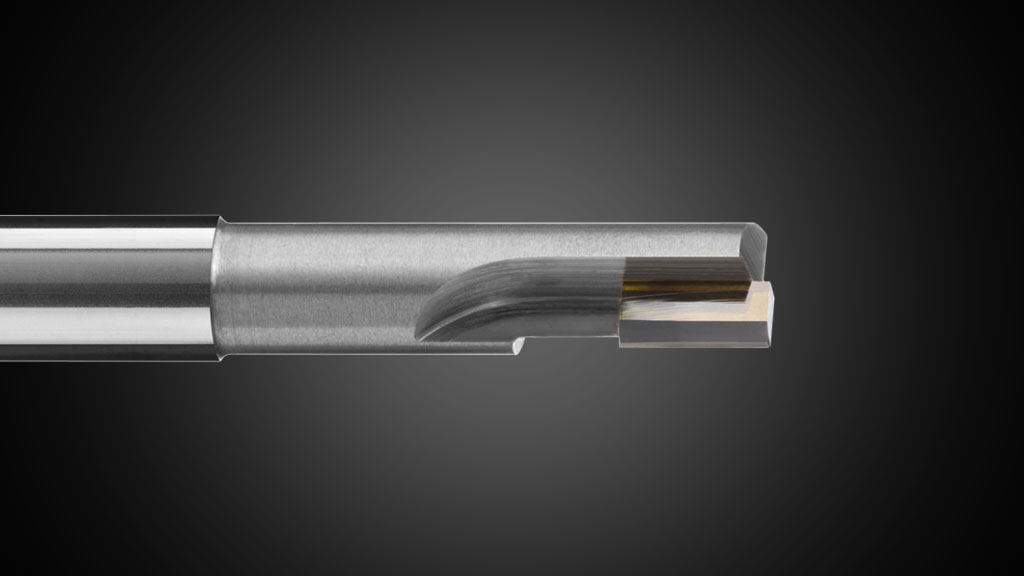

MCD polishing cutters

Polished letters or logos of any contour made of acrylic can be produced directly on your milling machine with this diamond cutter. Separate polishing machines become dispensable.

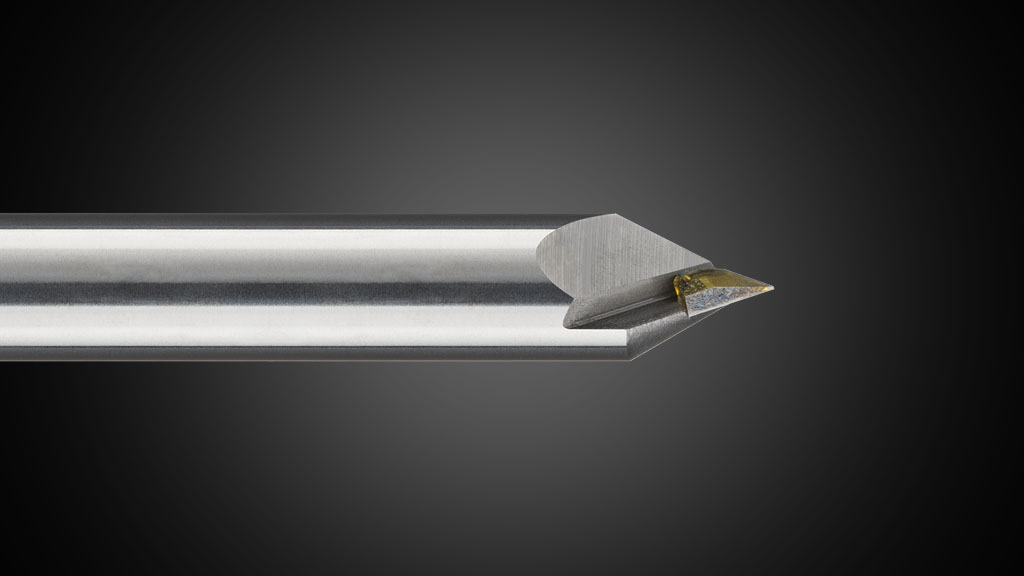

MCD polishing gravers

This tool with its attached diamond polishes engravings on sophisticated acrylic signboards etc. to a high gloss. It is available with a top angle of 60° and 90°.

PCD polishing cutters

For polishing acrylic glass letters or logos of any contour, this diamond cutter is ideally suited – with an extra-long cutting edge for polished edges without disturbing steps.

PCD polishing gravers

This diamond tool ensures shiny engravings; the extra-long cutting edge also makes it suitable for very deep engravings – with 60 and 90 degrees top angle.

CVD cutters

Diamond tools with CVD cutting plates distinguish themselves by an especially great hardness and endurance; ideal for abrasive materials.