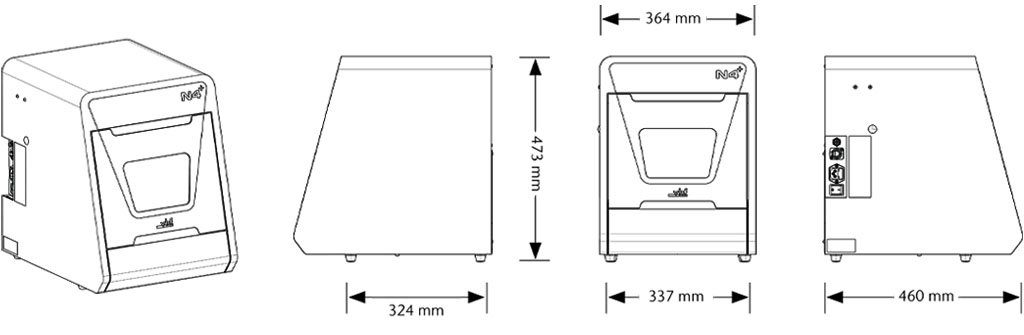

Construction

Machine bed made of solid cast aluminum body

Housing

Sheet steel housing, white high-gloss lacquer finish, with working chamber flap and cooling liquid tank integrated in the drawer

Number of axes

4

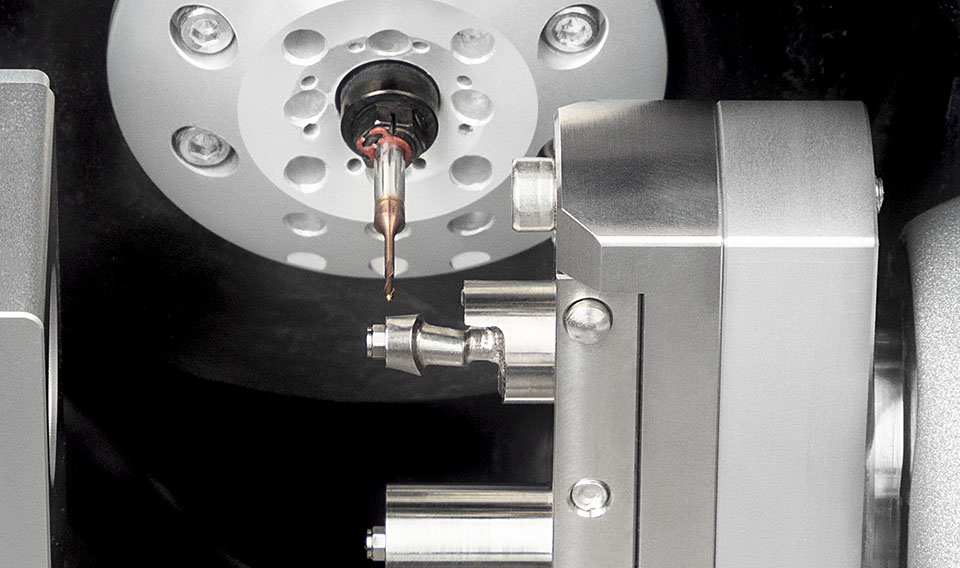

Linear axes X-/Y-/Z-axis

Precision ball screws, rolled version · motors with resolution < 1 μm · ground precision guides made of steel · repetition accuracy ± 0.003 mm

Rotary axis A-axis

Rotary axis with high run-out accuracy · rotation angle: 200°

Control unit

4-axis simultaneous control electronics with continuous path progression and dynamic pre-calculation · hardware-based real-time operating system with standardized command set · FPGA-integrated processor · updateable hardware · real-time path calculation via dedicated hardware engines in the FPGA · four-quadrant control of the motors for particularly smooth running · multiple analogue and digital I/Os for controlling the peripherals · integrated inverter for synchronous and asynchronous motors, electronic gate detection · Ethernet and USB interface

Lighting

RGB LED lighting with status display

Camera system

Integrated in the working chamber for easy remote support and possibility of internal recording