Construction

Machine bed made of solid cast aluminum body

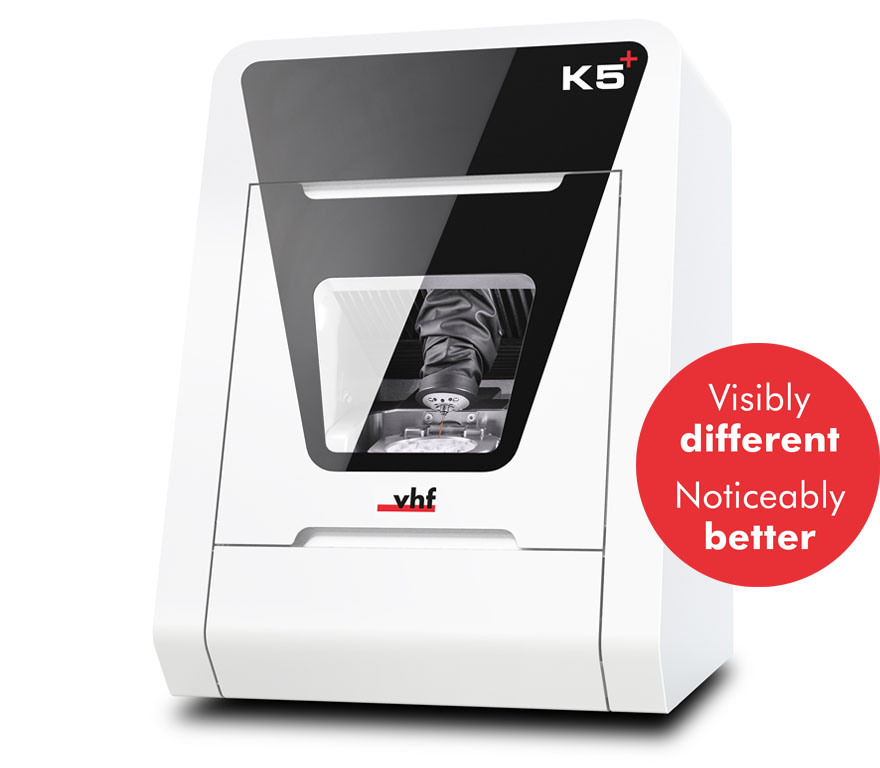

Housing

Sheet steel housing, white high-gloss lacquer finish with working chamber flap and accessories drawer

Number of axes

5

Linear axes X-/Y-/Z-axis

Precision ball screws, rolled version · motors with resolution < 1 μm · ground precision guides made of high-alloyed steel · repetition accuracy ± 0.003 mm

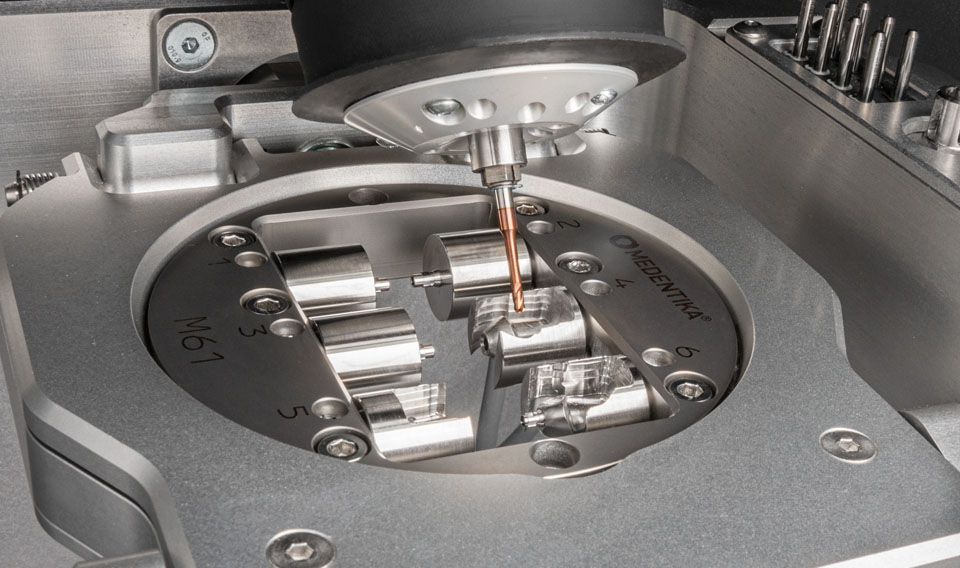

Rotary axis A-axis

Backlash-free Harmonic-Drive® with the highest angular precision · rotation angle: 360°, infinite

Rotary axis B-axis

Precision ball screw with rotary transmission · rotation angle: ± 35° · axis arrangement in the workpiece

Control unit

5-axis simultaneous control electronics with continuous path progression and dynamic pre-calculation · hardware-based real-time operating system with standardized instruction set · FPGA-integrated processor · updateable hardware · real-time path calculation via dedicated hardware engines in the FPGA · four-quadrant control of the motors for particularly smooth running · multiple analogue and digital I/Os for controlling the peripherals · integrated inverter for synchronous and asynchronous motors, electronic gate detection · Ethernet and USB interface

Lighting

RGB LED lighting with status display in the working chamber

Camera system

Integrated in the working chamber for easy remote support and possibility of internal recording

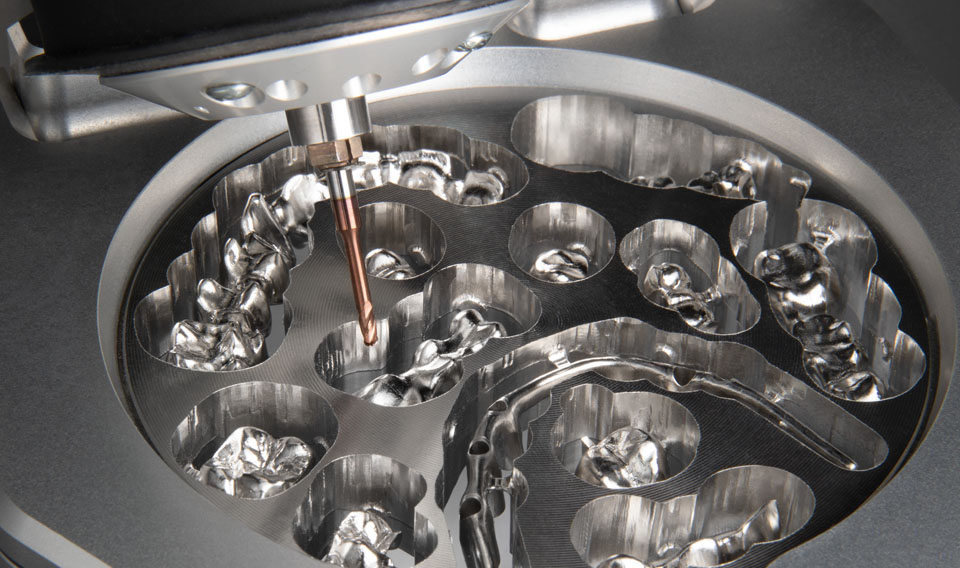

ATB

Integrated Administrated Tool Board (ATB) for 30 tools