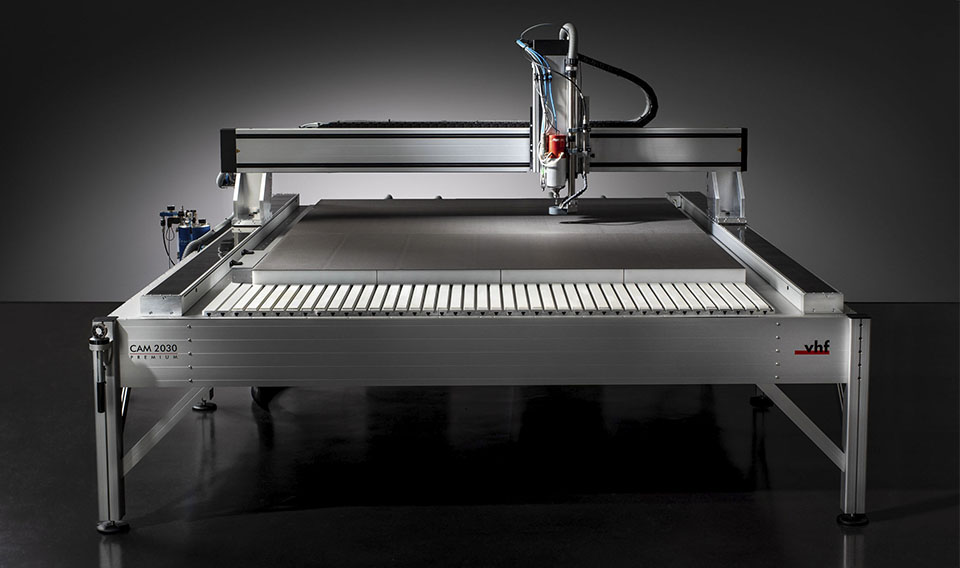

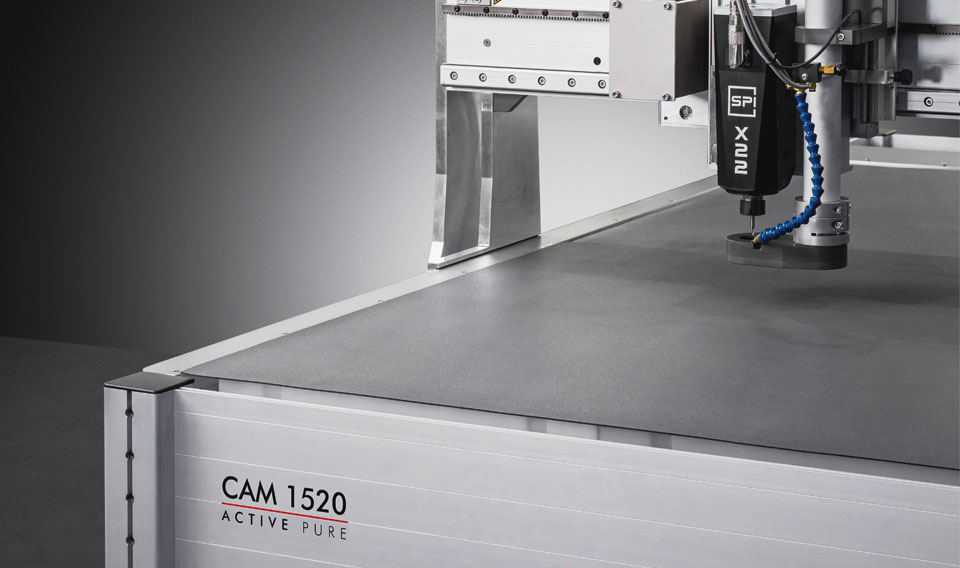

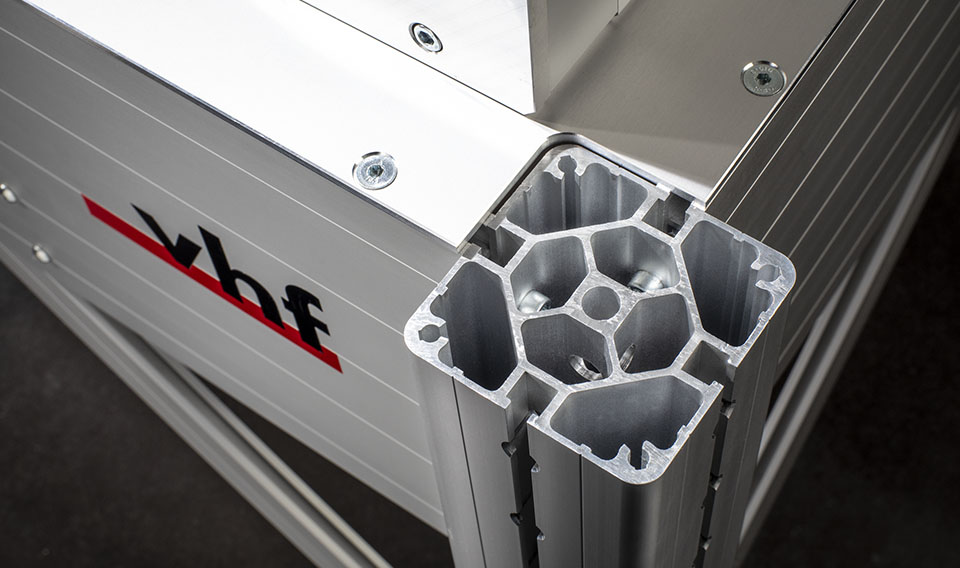

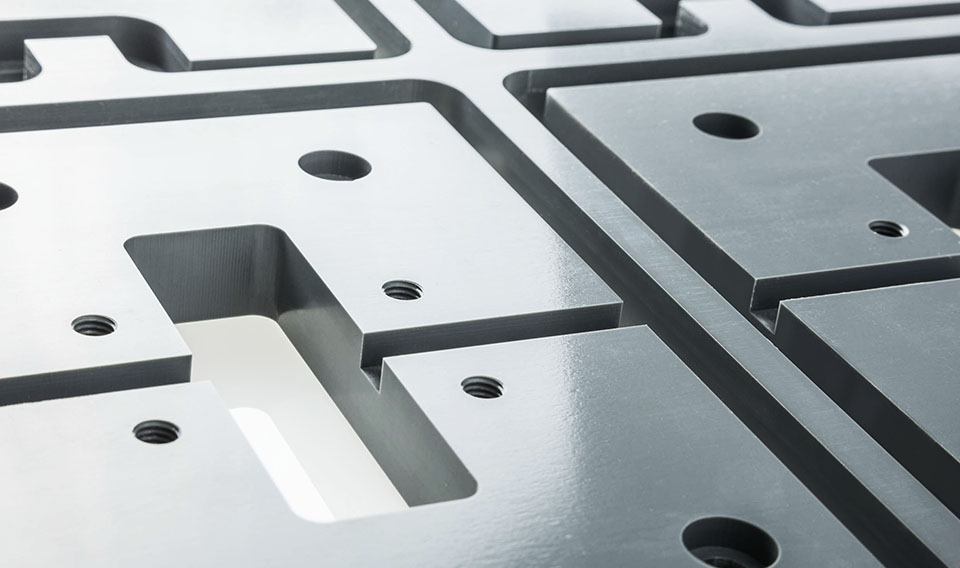

The vhf milling machines can be equipped exactly according to your requirements and can do much more than milling plates: also cutting, drilling, engraving, chamfering, milling slots or pockets, producing threads or grooves – no problem at all. Thanks to their modular construction, our CNC milling machines are manufactured individually according to your specifications. Whether 1 x 1 m, 1.5 x 2 m, 2 x 3 m or another positioning range up to 3 x 8 m – size variety is standard for us.

vhf is far more than a machine manufacturer. We live the all-from-one-hand principle down to the detail: this includes not only the software development, but also the development and production of the CNC milling machines, the CNC controllers as well as the tools. Everything is a perfect match!

With vhf milling machines, you as a user will not only benefit from the latest CNC milling technology, but also from an excellent support so that you can always work productively. We reliably support you with our profound expertise about portal milling machines, tools and CAM software – before and after your purchase.

Discover your next milling machine here and let us give you competent and comprehensive advice. We are sure to find a suitable solution for your applications!