Components and software

For your individual machine.

Milling machines from vhf are built from modules. We put together a machine for your company that meets your specifications exactly. When we design the machines, we factor in your expectations of maximum operating efficiency and modern versatility. And if your requirements change, you can take advantage of our many retrofit options.

Machining units

The right machining unit for your application is vital for the quality of the final results. So we offer a wide choice of machining units for every application and in every price segment.

Rotary current spindles

Provide plenty of power for heavy milling jobs. Plus, rotary current spindles let you work with the largest tool diameters.

High-frequency spindles

You get the best results from these spindles when you work at high speeds and fast feed rates.

Oscillating tangential cutting head

The first choice for materials such as foams, cardboard (composite), rubber, foils, tarpaulins and textiles: an oscillating cutter that moves up and down at high speed.

Multi unit

The ideal extra: consisting of the oscillating tangential cutting head and a universal head for straight cuts, V cuts, and creasing.

Fixing devices

Your workpieces can be fastened to the machine by means of a vacuum table, using manual or pneumatic clamps, or with adhesive foils. Our solutions minimize your set-up times, no matter whether you choose the full vacuum table or the partitioned clamping area.

Vacuum tables

The special vacuum table also enables you to machine fretwork and outlines. The vacuum table with grid is recommended if you particularly intend to engrave or mill pockets.

T-slot fixing set

Manual and pneumatic sets are available that enable you to fasten your workpiece directly using the T-slots.

Polystyrene surface

Your workpieces are fastened to the polystyrene surface using either T-slot clamps or a special adhesive film.

Rotary axes

The different versions of our rotary axes enable you to machine your workpieces from all sides.

Measuring devices

Various ways of automatically measuring your workpieces not only save you time during the set-up process. What is even more important is that they compensate for any inaccuracies that often occur in the thickness of the material or in its length and width.

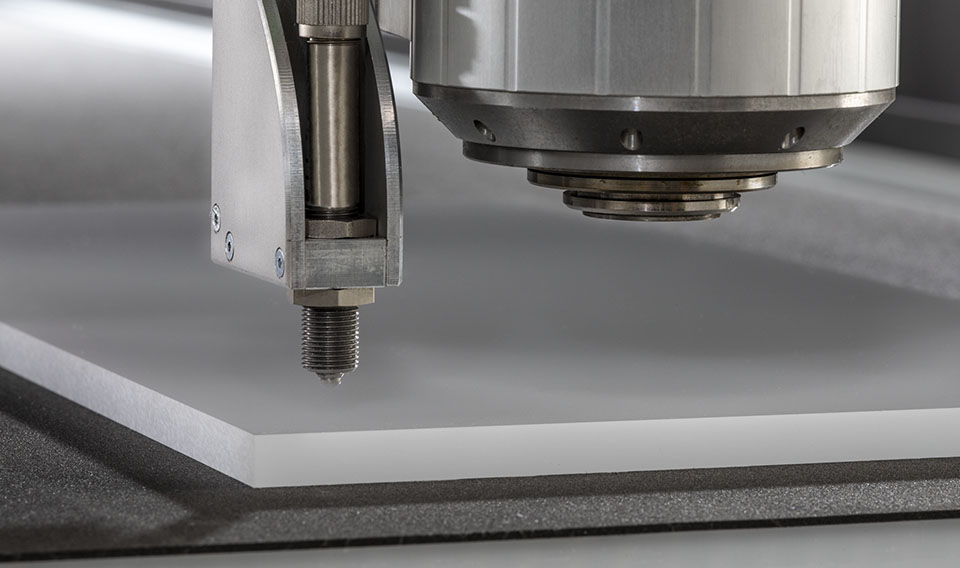

Workpiece levelling

This measuring device eliminates any tolerances in the material thickness and ensures the tool penetrates evenly across the workpiece.

Automatic z-axis adjustment

This useful tool measures the thickness of the material in seconds.

Optical workpiece recognition

This module enables the optical recognition of your workpieces or any fiducials printed on them.

Additional equipment

Add original vhf accessories to your CNC milling machine and improve your results, or make your work even easier.

Please note that for safety reasons, all machines must be fitted with a vacuum extraction system or a housing. We also offer individual safety concepts for your company.

Automatic tool changer

You can make your entire workflow more efficient by adding an automatic tool changer.

Dust and aluminum extraction

Our dust extractors offer you an intelligent concept for removing swarf and dust. The vhf vacuum system for aluminum machining combines the advantages of liquid cooling with those of vacuum extraction.

Cooling and spraying unit

In many materials, the tools have to be cooled. This increases their working life and you get clean cutting edges.

Minimum quantity lubrication

The most technically sophisticated solution for cooling tools is electronically controlled minimum quantity lubrication.

Safety equipment

There are various kinds of other safety measures that can be taken depending on the individual circumstances. Machine housings also ensure a clean working environment and reduce noise.

System racks

All the controller components can be installed in a lockable 19 inch system rack.

Software

What would a CNC milling machine be without the right software to import your projects smoothly from all the various CAD and DTP programs available?

Cenon

Cenon is the universal manufacturing software for your CNC milling machine. You can create your project either from your favorite design software (AutoCAD, Illustrator, etc.) or directly in Cenon.

Cenon lets you concentrate fully on the key steps of the CAM output. Intelligent algorithms take care of transferring your graphics to the milling machine.

Cenon CCD

The Cenon CCD module is used for the optical measurement of printed workpieces. This gets rid of a common problem: the workpiece has been carefully printed, but when it is then cut out, the borders do not match exactly.

3D-machining

There are different software packages for producing three-dimensional objects, each optimized for specific applications.

Third-party CAM

With our vhf output software you can easily process your self-generated CAM data on our machines via post-processor.

Engraving fonts

High-quality single or multi-line fonts which have been specially developed for engraving and do not need to be reamed.